Listen, repeat, memorize!

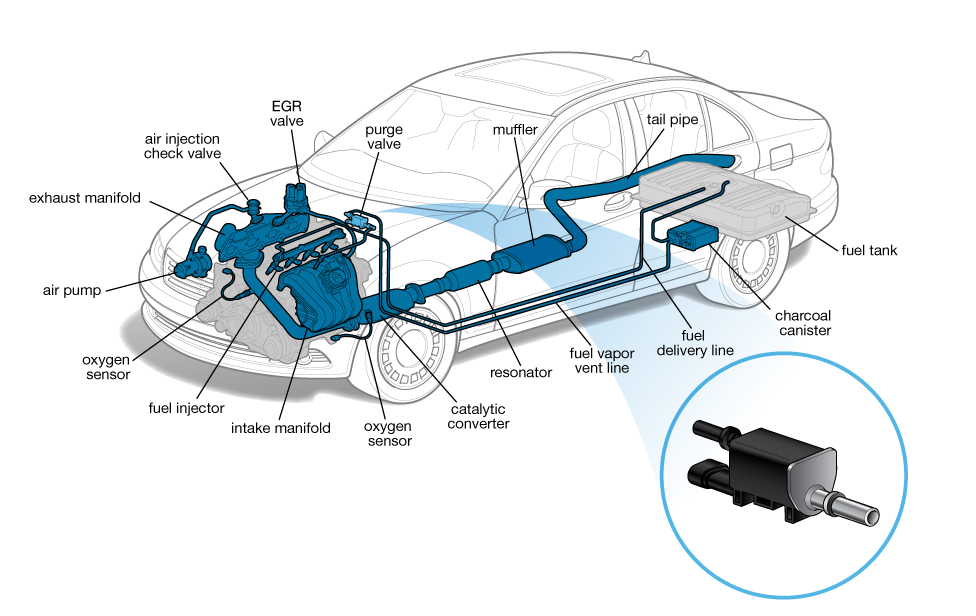

Exhaust & Emissions - Canister Purge Valve

A canister purge valve is a solenoid valve controlled by the Power Train Control Module.

The Power Train Control Module is a control unit that determines the ignition timing, fuel amounts and other parameters needed to keep the engine running.

In the charcoal canister, the purge valve is the opening that releases fuel vapors that were absorbed by the charcoal back into the engine for combustion.

A failed purge valve is one of many causes for check engine lights, and it is often difficult for mechanics to diagnose.

The canister purge valve serves as part of the emission control system in a car, and it measures the flow and amount of fuel vapor that is recycled into the combustion process via the charcoal canister, or fuel vapor storage device.

Canister purge valves are also used in “leak tests,” by allowing a vacuum to be created throughout the fuel storage system when the valve is closed, thus preventing outside air from entering the system.

Replacing or upgrading your valve ensures that it works effortlessly to measure the quantity of fuel vapor that’s reprocessed into the fuel vapor storage, instead of releasing harmful toxins and gases into the atmosphere.

Listen, repeat, memorize!

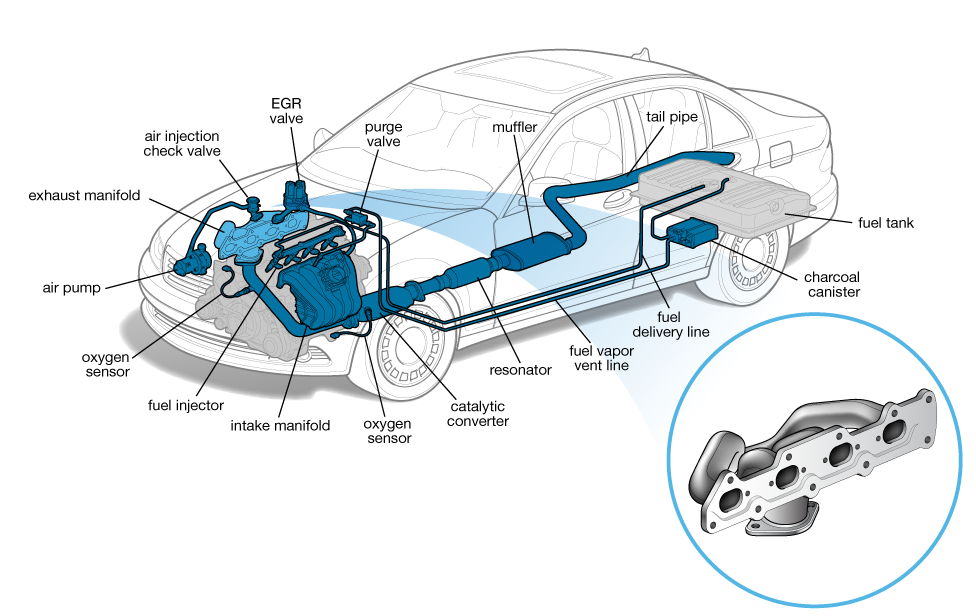

Exhaust & Emissions - Exhaust Manifold

Bolted directly to the engine block, the exhaust manifold is the first section of a vehicle’s exhaust system.

It funnels exhaust gases from all the cylinders and routes them to the car’s catalytic converter.

V-type engines have a separate manifold for each cylinder bank.

A leak in the exhaust manifold or its gasket can allow exhaust gases to escape, which poses a health hazard to the car’s occupants and can result in erroneous readings by the oxygen sensor, triggering a check engine light.

Larger holes in a manifold will produce loud exhaust noise.

Listen to the Text:

Listen, repeat, memorize!

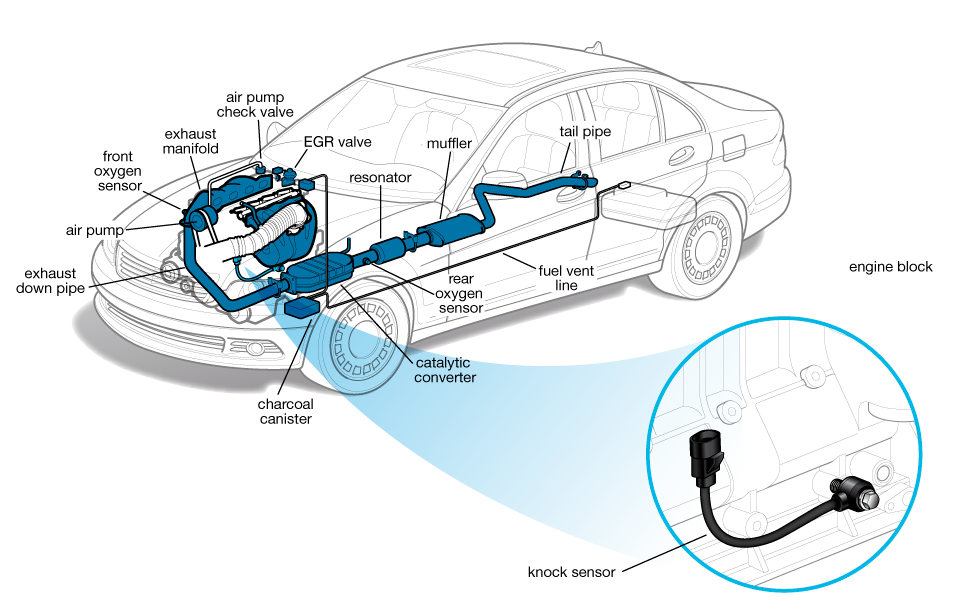

Exhaust & Emissions - Knock Sensor

The engine’s knock sensor (or sensors) detects preignition and detonation, potentially damaging forms of abnormal combustion.

Though full-blown knocking and pinging are audible to the human ear, the knock sensor detects imperceptible levels.

When knocking is detected, the engine’s computer can retard the spark plug timing to prevent it.

In the event of knock sensor failure, the driver may experience audible knocking or pinging and/or diminished acceleration, which is sometimes accompanied by decreased gas mileage.

A check engine light is a likely result.

Listen to the Text:

Listen, repeat, memorize!

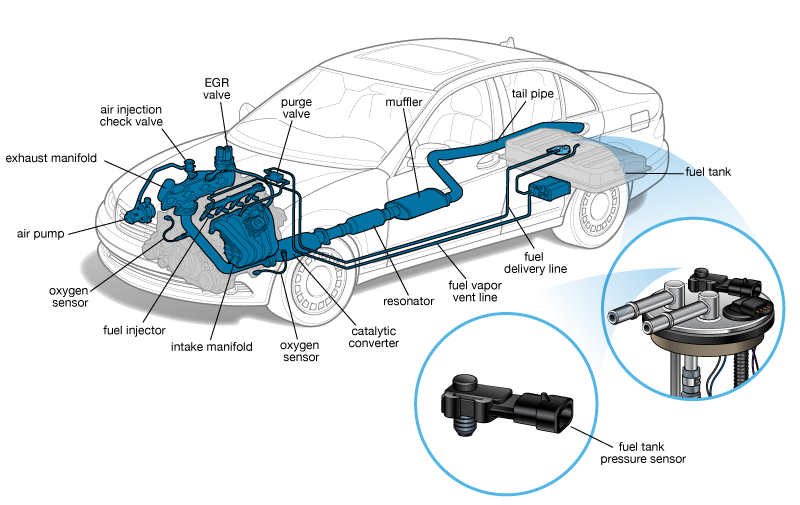

Fuel Tank Pressure Sensor

The fuel tank pressure sensor is part of the fuel pump assembly and is mounted on top of the tank or inside the tank.

It’s part of the evaporative emissions system (commonly referred to as “EVAP”) and reads pressure in the fuel system to detect evaporative leaks, such as a loose or faulty gas cap.

Fuel vapors are supposed to be contained in the EVAP system, and leaks can allow vapors to escape into the atmosphere.

The sensor is connected to the engine computer, and when the sensor detects a leak, or if the sensor itself fails, it illuminates the “check engine” light.

Mechanics can read a trouble code to trace it to a leak in the evaporative emissions system or the sensor.

Fixing an evaporative leak may not require removing the fuel tank, but checking or replacing a faulty sensor usually does.

Listen to the Text: